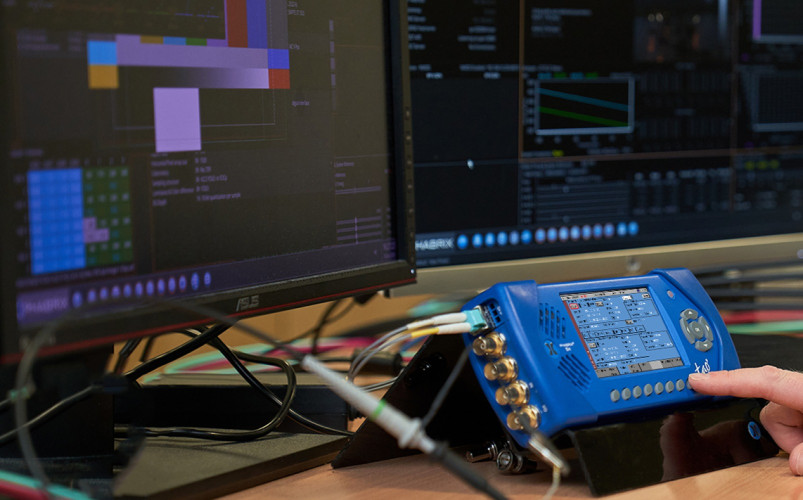

Everyone will have their own view as to the ‘critical’ items that have to be monitored constantly in broadcast. It was this need to offer a solution to QC that led PHABRIX to create a new range of products moving on from the highly successful PHABRIX Sx hand held products to a rack mount solution. The PHABRIX Rx series was released at NAB this year specifically to monitor video signals 24/7.

Whereas the principal items being monitored will already be well known by most readers the way PHABRIX presents this information and the choice of modular options available across technologies. The ability to support video, audio, ASI, Dolby etc., provides an engineer with a single reliable source for a range of signal monitoring.

The big boys of monitoring are of course video, audio and data so perhaps this article could have more usefully been entitled ‘What are the top 3 items you need to monitor? However in examining each of the three in more detail the list expands to 10. So in no particular order:

1. Video.

The first check is whether the picture or content being transmitted is visible. That’s not to say that the picture/video alone is the key. Many an inexperienced operator has assumed that because there’s a moving picture on the screen all is well - the seasoned amongst us can tell you that maybe that signal is just about to fall over a cliff. The PHABRIX Rx 2000 comes equipped with two screens so that a video signal can be viewed alongside a separate screen for the instrumentation associated with that signal at all times. With its ability to monitor up to eight independent signals simultaneously, the PHABRIX Rx 2000 can also be configured to use its HDMI or SDI output to scale the video signals and monitoring data on a separate screen at 1920 x 1080 so both the engineer at the broadcast rack and the QC engineer in the central control room can access the same information at any scale and without any loss of immediacy. The instruments most associated with picture quality include the waveform and vectorscope which are usually on continuous display. An indication of gamut – out of range colours is also useful.

2. Picture information.

Video is video but what flavour? Is it 4:3, 16:9 and what standard is being broadcast – PAL, NTSC, HD 720p, 1080i ? We’ve moved a long way from SD to HD to now 3G and 3D and any monitoring system has to be equipped to auto sense all the different standards in use – critical information that needs to be displayed at all times.

3 Audio.

Having assumed that the picture being broadcast is indeed ‘Live’ the next thing to monitor is audio. It helps if the monitoring system does have some speakers connected so a very basic check can be made. There’s nothing like the human ear to pick out sound, but just as video needs some associated instrumentation to QC, audio requires the same. Normally a level meter displays the presence of audio and unless it’s a single tone, these bars are going to be moving. There can be up to 16 channels of audio so each channel has to be monitored separately. The Channel Status for the selected audio channel can be displayed in decoded form as well as a hexadecimal dump of the bytes. If AES inputs are present these need to be monitored. Surround sound metering is also important.

4 Dolby.

The ability to monitor a Dolby signal is essential. As viewers increasingly move toward sophisticated viewing environments Dolby is present either as Dolby E, Dolby D and Dolby D plus. Whether monitored as Dolby metadata and levels or full Dolby decode, broadcasters who are transporting audio signals as encoded Dolby need to make sure that their audio is correctly timed and contains the correct meta-data.

5 Loudness.

Mandatory in many countries, loudness monitoring is becoming a hot topic in the UK. Differences in audio levels between programs, or between programs and commercials, are a major annoyance to TV viewers. There is a need both to check loudness on transmission and a way of proving levels were transmitted within agreed parameters should the broadcaster receive a complaint.

6. EDH/CRC error handling.

Depending on the video standard being monitored, errors in the video signal can be monitored digitally using EDH (error detection and handling) and CRC (cyclic redundancy check) . The Rx 2000 does this by counting the bits in one frame and adding it to the beginning of the following frame - if they do not match then the error is flagged. This very basic test is a must when monitoring SDI signals and is an early detector of possible problems with the signal.

7. Eye and Jitter.

PHABRIX has made a name for itself providing a cost effective, laboratory quality eye and jitter analyser which would normally be too expensive to be found in typical QC environments. PHABRIX technology has changed all that with the Rx 2000 bringing the price for this sophisticated monitoring instrument within the range of most broadcasters If the EDH or CRC errors have been flagged a secondary look at an eye pattern or jitter waveform will establish whether it is a true bit error. Jitter measurement for alignment should be within 0.2UI for SD or 0.3UI for HD or 3G and it is the alignment jitter which is the most important when it comes to fault finding. PHABRIX Rx 2000 screen will show both numbers or thermometers to indicate the signal is within limits. If the ‘eye’ pattern is fuzzy or blurred this will also indicate excessive jitter. Seeing this response may mean that your transmission is indeed approaching the cliff referred to earlier!

8. Cable length.

Many may think this is an unusual item to monitor however the Rx can check cable length and be set to flag an error if this is exceeded. Monitoring the cable length will also keep you away from the cliff edge for if the cable exceeds the set length, (normally 50m for SD and 20m for HD), then depending on the quality of the cable the headroom of the SDI signal will drop resulting in errors.

9 Ancillary data.

Most SDI signals carry a lot more information than just video and audio. We were first introduced to this as Teletext in the 1970’s, the additional information carried in vertical blanking interval of video, however today an SDI signal carries a whole lot more from wide screen signalling to captions. Having the ability to view the extra data in the signal is a must for all monitoring solutions. The PHABRIX Rx 2000 can be set to show just those selected by the engineer or the ANC status toolset can ‘sniff’ them out and display what’s contained in the signal.

10 Logging.

Finally any monitoring system has to be able to tell you what is being monitored and keep a record of events. This can be used in several ways. At any time an engineer can view the system from the logging screen being updated real-time with any errors set up to show in red or freeze. Alternatively the logs can be exported into an excel worksheet for more in depth analysis of events over time.

The important thing to remember with today’s monitoring solutions is that they need to be easy to use and show the pertinent information quickly and precisely. From this an engineer can make choices and solve any problems that may be presented during QC. After all, it may be the difference between a good on air experience or a bad one.

The Rx 2000 is available from PHABRIX now. For more information contact www.phabrix.com or call 01635 276302.